Sheet metal laser cutting is a process that allows to obtain metal parts cut by design for various product and industrial sectors.

The machines we use to perform sheet metal laser cutting operations allow us to cut metals with thicknesses up to 15 mm and perform:

- laser cutting on iron sheets

- laser cutting on stainless steel sheets

- laser cutting on aluminium sheets

- laser cutting on pre-galvanised sheets

- laser cutting on copper sheets

- laser cutting on brass sheets

- laser cutting on titanium sheets

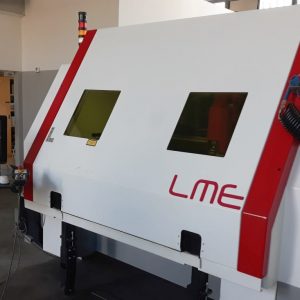

The machines we use to perform the different cutting processes are fibre optic lasers with 3000 mm x 1500 mm work surfaces.

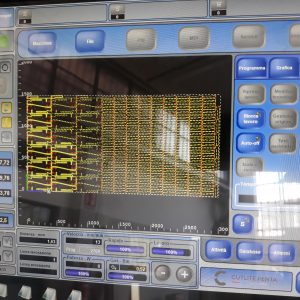

The sheet metal laser cutting machines are part of the Industry 4.0 investment program and therefore allow us to check in real time the state of laser cutting operations, with special dedicated management programs, as well as to obtain immediate assistance from the manufacturer in case of any failures or for the optimisation of production processes.

The flexibility of the machinery is optimal for rapid prototyping processes with maximum reliability.