Automatic moulding

S.I.MO srl is able to produce parts in high volumes through automatic moulding. This process is carried out using progressive moulds, powered by coils, with the aid of specific electronically-controlled machinery. These also include automatic processes for lubrication, evacuation of finished parts and scraps, and all the necessary controls to guarantee the protection of the machinery mould and the necessary quality standard of the end product.

Automatic moulding may be applied to all types of moulding (shearing, bending and drawing) and to all types of materials (iron, stainless steel, aluminium, copper, brass, titanium, etc.) and it is performed, based on volumes, either with the aid of the operator or independently, guaranteeing high quality standards and very low production costs.

Manual moulding

SIMO Srl machines small volumes of items through manual moulding. This process must be carried out with the supervision of a certified operator through shearing, bending and deep drawing. The materials that may be machined are iron, stainless steel, aluminium, copper, brass and titanium with presses from 10 to 500 tonnes and with work surfaces up to 2,000 x 1,600 mm.

Manual moulding allows to produce a great diversity of products: from small sized components for electronic applications to kitchen stoves.

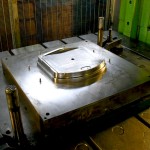

Deep drawing

One of the company’s main processes is deep drawing. It consists of a technological process through which a deformed metal sheet takes on one of the following forms: box-like, cylindrical, cup-shaped and/or funnel-shaped. This procedure, carried out by specialised staff and with a 500-tonne hydraulic press, makes it possible to create objects with deep cavities, such as: engine oil cups, pots, bottoms for pressure vessels, and other various parts made of iron, stainless steel, aluminium, copper, brass and titanium.

The large dimensions of our hydraulic presses (2,000 mm x 1,600 mm work surface, 1,100 mm run) allow to create large components.